Cost-effective, flexible and versatile

Technical details of the welding process

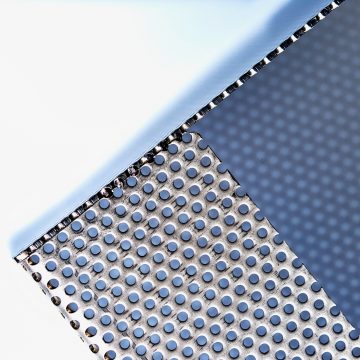

The penwelder is operated exclusively in the pulsed deep welding process. Work is carried out without filler material, which is why a technical zero gap is required. This means that the joining gap must not exceed 10% of the material thickness, but not greater than 0.15-0.2 mm. During deep welding, the laser beam not only melts the metal but also forms a deep, narrow, steam-filled hole – the so-called steam capillary – or keyhole. The metal melt flows around this steam capillary and solidifies at its back. In this way, a narrow, deep weld seam is formed with a uniform structure and a high strength. Basically, this welding process is characterized by high efficiency and high welding speeds. The heat input is very focused, resulting in low distortion or low start-up colours. In addition, many materials that are considered non-weldable become weldable.

Advantages

- Little to no delay of the component due to pinpoint, precise energy input

- Can be used immediately, no training necessary

- Flexible – even for intricate seam geometries

- Integrated protective gas supply

- Lunker-free welds

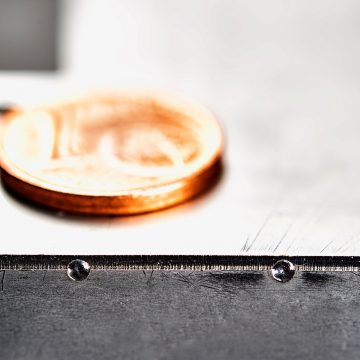

- Pulsed operation with welding depth up to 2mm

- Minimal effort in rework

Materials

- Stainless steel

- Titan

- Black steel

- Aluminum

Finetuning the welding result

In pulsed mode, depending on the power of the laser source, we can set 3 parameters:

(1) the peak pulse power, (2) the pulse duration, and (3) the pulse frequency.

These parameters determine the welding result in terms of welding penetration depth, maximum welding speed and seam surface. Furthermore, the beam shape can be adjusted via the infinitely variable focus setting.

- average laser power up to max 500 W

- Pulse duration 1 to 50 ms

- Peak pulse power 3000-4000 W

- welding speed max. 4m/min

- welding depth max. 3mm