We guide the laser beam by hand

Hand Laser System Technology

The team at Blue Lasertools GmbH has been developing and manufacturing hand-held laser welding devices for more than 10 years. Mobile hand-held laser welding devices expand the possibilities of laser application welding in tool and mould manufacturing and laser fine welding in sheet metal processing. Laser hand welding involves moving a laser processing optic by hand along the workpiece. Very large and heavy tools and shapes can be welded regardless of location, even in a tense state if necessary. The machining head is small and with its low weight is also suitable for longer-lasting welding tasks. The laser beam is guided to the workpiece via a flexible laser light cable that is variable in length. The laser device can therefore be set up independently of the place of use.

Laser-Pen

- Contact tip for reproducible welding results with protective gas supply

- Hand switch that triggers the laser source in conjunction with the foot switch

- Protective glass for optics, can be swapped by loosening the contact tip

Control Box

- Optional with a program choice panel with 4 welding programs

- Error-proof Siemens control S7 1200

Safety-Footswitch

- Integration via control

- Essential part of the 3-point security concept (contact press kick)

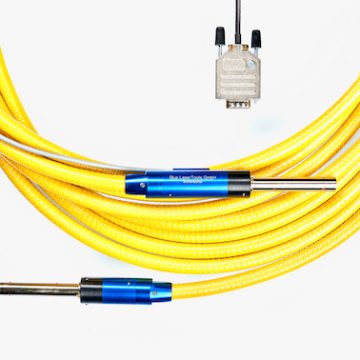

Laserlightcable

- Represents the optical connection between laser source and penwelder

- Depending on the manufacturer, plug type A (trump) or plug type QBH (SPI, IPG or Coherent) can be used, further plug types on request

Compatible Laser Sources

The Penwelder is the only system for hand-held laser welding that can be easily and securely connected to any common solid-state laser source. The connection is made via a second output at the laser source. When welding with the penwelder, the welding robot cannot be operated and vice versa.

Laser safety during operation

A laser handwelding device is subject to laser protection class 4 in operation. As a result, different measures are required on the customer side to ensure laser safety, such as the appropriate briefing of the employees, the wearing of special protective equipment and the establishment of a dedicated laser safety area.

Lasersafety-Goggles

Lasersafety-Glove

Lasersafety-Cabin